Intro

The ear has probably been the symbol, the face, of tissue engineering and particularly bioprinting for many years. Consider the famous Vacanti ear back in 1996 that captured audiences around the world in both exciting and stomach wrenching ways. Atala then in 2016 followed with his own 3D bioprinted version that yet again captivated audiences. Last, when the bioprinting industry started to go more mainstream both Allevi (formerly known as BioBots) and Cellink both used the ear as a way to show they had mastered the technology.

The ear is the subtle yet signature piece in a human face that has a high degree of complexity given it’s contours yet is a single material of cartilage. Making the macroacrchitecture the relevant piece. Its 3D shape is recognizable on first glance just by looking at it. This is in contrast to a piece of skin or a piece of liver. The general person doesn’t recognize other internal organ type as much as the ear when it is by itself. Even a nose is sometimes difficult to distinguish. So, what was in the 90s a source of science fiction, really began to take hold of scientist in gaining attempts at making, well a real implantable human ear.

Microtia

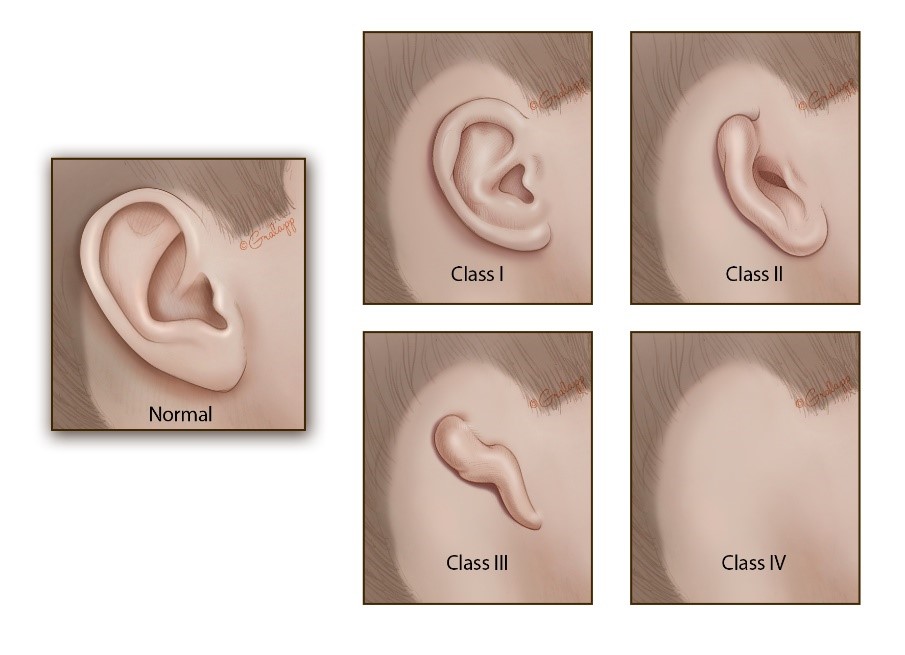

As important as the ear has been as a tool of imagination for the field, there is a recurring disease that is seen in the population called microtia that benefits from ear implants. Microtia is a congenital deformity where the external ear is underdeveloped, ranging in severity from a slightly smaller ear with normal structures (Grade I) to complete absence of the ear (Grade IV, also known as anotia). This condition, which can affect one or both ears, often results in hearing loss due to associated abnormalities in the ear canal and middle ear structures. It can occur due to genetic factors or environmental influences during pregnancy. Clinicians have postulated the idea of using 3D bioprinting as a way to make a personalized ear implant that would improve both function as well as aesthetic appearance of a patient.

Fig 1. Different classes of Microtia

Today depending on the severity, the therapy includes in the lightest case to wear a silicone ear over the defect and in the more serious case requires an implant for reconstruction.

The First Standard Solution

In 1959, Dr. Tanzer pioneered the use of rib cartilage for autologous microtia reconstruction. While the procedure is well accepted with less complication than alternatives, it can only usually be done when the child is 10 years old and is an involved complex procedure. Cartilage reconstruction is an invasive technique that requires between 2–5 surgeries. Ear reconstruction with rib cartilage must be delayed is old enough to have sufficient cartilage to make an adult-sized ear, typically between 7–10 years of age. First the cartilage from several ribs is removed through an incision on the child’s chest The cartilage is carved and pieced together to create an ear framework. This framework is buried under the scalp and after the ear has healed, more surgeries are required to complete the reconstruction: elevating the ear away from the scalp, repositioning the earlobe and other adjustments. Step by step framework can be found here. While there can be great success for these patients, as stated the process is quite invasive, lengthy, complex.

One Doctor That Changed the Standard

It’s interesting to see, as Dr. John Reinisch states himself the basic method of cartilage harvest framework, assembly with stainless steel wire, placement of the skin ear reconstruction is pretty much the same as it has been for the last 60 years or so. In the early 1990s, Dr. Reinisch, who actually knew Dr. Tanzer, pioneered a new way to make microtia repair using Medpor, which is Stryker’s porous polyethylene. Side note a company call Poriferous has a similar material Su-Por also porous polyethylene for this purpose. This method offers many benefits, given the procedure can be done on patients as early as 2-3 years old, can be done in an outpatient facility, and can be done in a single surgery. It basically uses a non-active biocompatible plastic that gives shape to the skin and ear to allow patients and parents to benefit in a variety of ways. It also can be done as early as 3 years old because did you know by the age of 3 the year has reached 85% of its size for a humans’ entire life. It was a great idea, and has really create a revolution in the way ear repair is being done. There are some draw backs such as fractures that occur later in life, yet the consensus has been that the benefits are certainly outweighing the risks.

Fig 2. Ear reconstruction before & after 4 year old girl with bilaterial microtia after 3 years ear & canal reconstruction

One Group Helping Restore the Inner Ear Canal

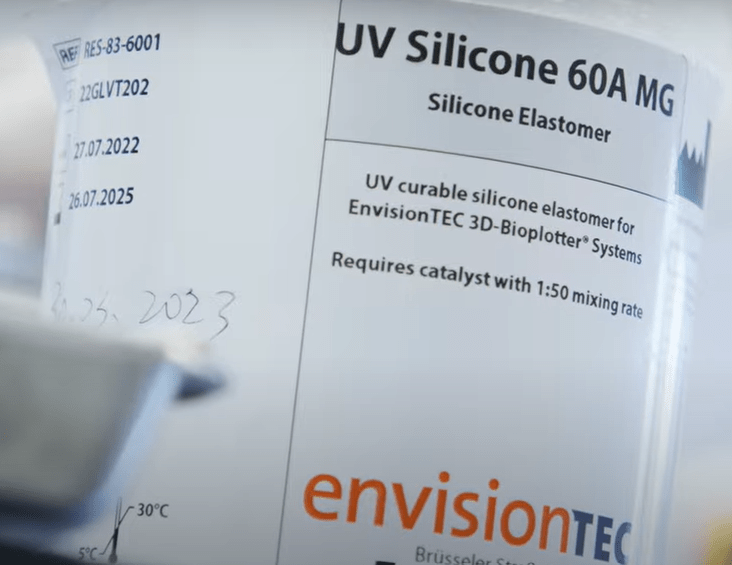

Apart from the standard made with Dr. Reinisch, which is sculpting Medpor by hand. There is a one group particularly stands out when it has come to ear engineering to cure microtia. It is an awesome organization really doing some breakthrough work in many areas of tissue engineering, the Hannover Medical School. One of their most exciting works, which pertains to this article, is the recent implantation of a drug infused silicone implant to help with microtia. There isn’t any publication, mostly a patent and a video that gives indication as to what idea is being done.

The school uses an off the shelf 3D Bioplotter as well as medical grade UV curable silicone elastomer from EnvisionTec that they infuse with drug releasing compounds to reduce inflammation and scarring and accelerate healing.

The two interesting aspects here is first, there was an implant to a patient. It was specifically designed to be able to reconstruct a patient who had microtia to support the healing of the inner ear. And while the patient will need to have the silicone piece removed in the future after healing, it shows real value being imparted to a patient.

The other interesting point here that is noteworthy is that pieces of off the shelf components from EnvisionTec, both its Bioplotter and silicone are being use to be applied towards an application. This is exciting because it shows maturity of the industry to this point. Where researchers are beginning to understand how to take available engineered items and directly apply them towards an application. While that might not be the norm, the fact that there is a plethora of available bioprinters shows companies can begin to take off the shelf 3D bioprinters and rather than have to think about engineering new printers, they can specifically focus on the materials, and more importantly on the applications.

Fig 3. Taken from Desktop Health video displaying the new silicone implanted solution.

One Company – PrintBio

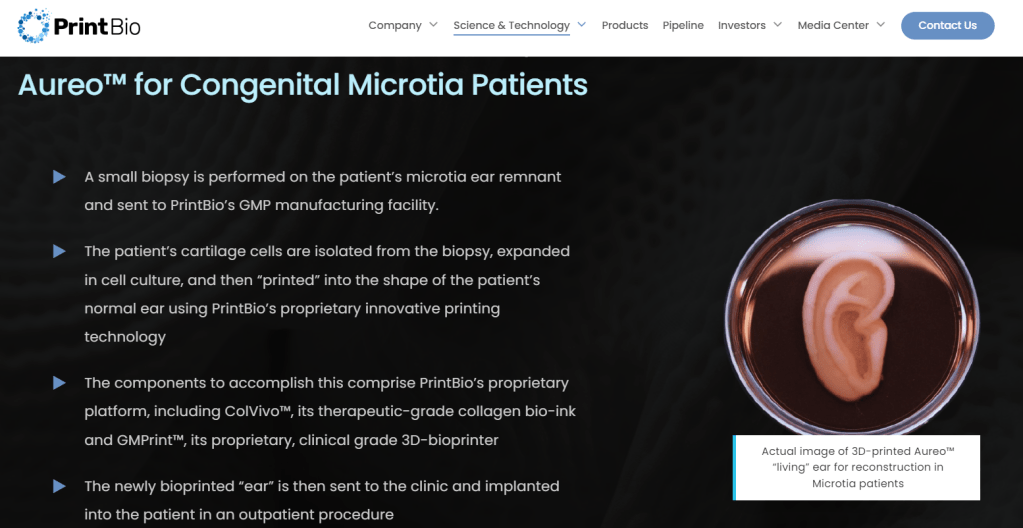

Last, as we think about the companies that have attempted to take on this challenge with novel techniques one company, 3DBio, now known as PrintBio, particularly stands out in this area. From the community they have been less present, quietly developing their solution.

The company was started by Daniel Cohen, Lawrence Bonassar, and Hod Lipsen out of Cornell. The group took some of the biomaterial and application work that Daniel Cohen had been working on out of Lawerence Bonassar tissue engineering lab in combination with Hod Lipson 3D printing expertise. The team envision the possibility to be able to 3D print a patient’s own cells in combination with a biomaterial to make an implantable ear. The vision was bold, and honestly something I believe even the pioneer Dr. Reinisch supports. It also takes the work of Medpor and EnvisionTec solution and integrates cells, particularly the patient’s own, to make a true cartilage replacement without the need to take a significant amount of autologous cartilage from other areas in the body.

It seems the company had a pipeline of tissue it was investigating, yet the initial product was for microtia repair. That is seen today on the company’s new website. It’s solution for microtia, Aureo, is built on 4 pieces of technology. 3DMatrix, a bioresorbable monofilament, ColVivo, a therapeutic-grade collagen, GMPrint, a therapeutic-grade 3D-bioprinter, and a “proprietary cell process” of collecting cells. The Aureo Process is elegant and exciting and can be seen from their website. To study it further, one can see their posted patents, for 3DMatrix its a biodegradable polymer potentially PLA,PGA, or PCL. For GM Print, it’s a printer that moves in an interesting fashion yet still foundational a 3D bioprinter. Last, ColVivo, is collagen prepared in a certain way to be able to achieve a collagen bioink.

These solutions did allow the company to the company to implant a 3D bioprinted ear into a patient back in 2022. It made headlines and was very exciting for an industry that had been holding this promise for many years. Fast forward to 2024, though and the company seems to have run out of funds only to be continued by one of the investors. The question is almost what happened? We can speculate that the problem lied in the downfall of the many other regenerative medicine companies that attempted to integrate cells. Lack of infrastructure and the need to innovate literally the entire process. While it might be appealing to have one’s own printer, it brings its own complexity of having to have a team to be able to innovate and iterate that process when a printer like the 3D Bioplotter could quite literally perform the same technological function it needs in a GMP way. The aspect of having to coordinate the patient’s cells and upscale them also adds complexity. While it’s certainly the dream to have patient cell’s ready on demand being able to offer acellular products, such as Integra Life Sciences does versus a company like Organogenesis, provides such a simplicity to supply chain logistics. So, while the company is on life support, they have exciting technology it’s just a matter of finding the right approach to make it a profitable one.

Fig 4. description of the Aureo process for Microtia patients

Conclusion

The work of Dr. Tanzer, Dr. Reinisch, Hannover Medical School, and PrintBio have all been influential in contribution solutions and ideas for the treatment of microtia. Dr. Tanzer provided a solution when there was really non-available. Dr. Reinisch, innovated a solution that could be done at the age of 3 with just one surgery. Hannover Medical school is thinking in the right way by taking off the shelf components specifically tailored to a specific application albeit not fully implantable yet. PrintBio while exciting is operating without partners in a too-far too soon solution that requires them to take a step back and evaluate how to simplify their operation, logistics, and solution to create a profitable product.

Hope this helps shed some light on the state of bioprinting ears.

Leave a comment