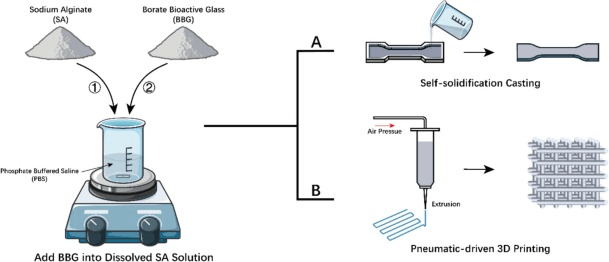

A recent study published in Science Direct highlights a new idea of integrating borate bioactive glass (BBG) with sodium alginate (SA) to enhances both printing precision and biocompatibility. This development has potential value for the creation of complex biological structures, including bone and soft tissue implants.

Figure taken directly from publication.

Sodium alginate, a natural polymer derived from seaweed, is widely used in 3D bioprinting due to its biocompatibility and affordability. However, traditional sodium alginate platforms often struggle with challenges such as low printing precision and uneven gelation, particularly when post-treatment with calcium ion solutions is required to solidify the printed structures. This is where borate bioactive glass (BBG) steps in to offer a novel solution.

Bioactive glasses are a group of reactive glass-ceramic materials that have been used in synthetic bone grafting. Unlike other biomaterials, such as hydroxyapatite or calcium phosphate, bioactive glass possesses unique anti-infective and angiogenic properties. These glasses are degradable in body fluids and can serve as carriers for delivering beneficial ions, thereby enhancing the healing process. Among them, borate bioactive glasses (BBGs) have shown superior bioactivity and bone healing capabilities compared to their silicate-based counterparts. BBGs have also demonstrated potential as drug delivery systems for treating infections and conditions like osteoporosis, and they are already used in FDA-approved wound dressings.

The new study reveals that BBG can improve 3D bioprinting applications by enabling self-solidification of sodium alginate through the controlled release of calcium ions. This process enhances the rheological properties of the material, leading to better precision and stability of the printed constructs. Unlike traditional methods that require post-printing calcium immersion to solidify the structure, BBG-SA hydrogels solidify during the printing process itself, resulting in higher structural accuracy and reduced shrinkage.

Beyond improving printing precision, BBG-SA hydrogels demonstrate excellent biocompatibility. They support cell adhesion and proliferation, crucial for tissue engineering, and promote osteogenic differentiation, essential for bone regeneration. These properties make them a highly promising material for a range of biomedical applications, including tissue engineering, regenerative medicine, and even biocompatible electronic devices.

Overall, the integration of borate bioactive glass with sodium alginate represents a new idea in 3D bioprinting. By offering improved control over gelation, enhanced biocompatibility, and better post-printing structural integrity, BBG-SA hydrogels has potential to open new possibilities in creating both bone and soft tissue implants.

About Hefei Institutes of Physical Science

The Hefei Institutes of Physical Science (HFIPS), part of the Chinese Academy of Sciences, is a leading research organization based in Hefei, Anhui Province, China. Established in 2001, HFIPS focuses on multidisciplinary scientific research across fields such as physical sciences, energy, materials science, environmental science, and life sciences. It is known for its cutting-edge work in nuclear fusion, high magnetic fields, and advanced materials, with multiple specialized institutes like the Institute of Plasma Physics and the High Magnetic Field Laboratory driving innovation and technological advancements in these areas.

Leave a comment