Biological Lattice Industries (BLI) recently announced a successful pre-seed funding round of $1.8 million, spearheaded by Uni.Fund, with contributions from several private investors. The company’s mission is to make biofabrication accessible for a broad range of applications, aiming to revolutionize the field through their pioneering technology. This funding will accelerate the development of BLI’s biofabrication platform, which seeks to provide researchers and organizations with the tools needed to push the boundaries of regenerative medicine, tissue engineering, and beyond particularly using melt elecrtrowritten microfluidics printing.

Addressing Biofabrication Challenges

Biofabrication, which involves creating biological structures that mimic natural tissues, holds enormous potential in healthcare, drug development, and biotechnology. However, high costs, technical complexity, and limited accessibility have historically restricted its widespread adoption. BLI aims to break down these barriers by developing an affordable, scalable biofabrication platform that democratizes access to cutting-edge bioprinting technologies with a workflow program that has nodes. They also state to be using artificial intelligence for these nodes and their foundational paper was in melt electrowritten three-dimensional biomaterial substrates. The paper can be found here.

With its recent funding, BLI plans to expand its team and enhance its platform, focusing on making biofabrication more user-friendly and efficient. The company aims to serve academic researchers, biotech companies, and other institutions interested in utilizing biofabrication techniques to advance their work.

Melt Electrowritten Microfluidics Printing

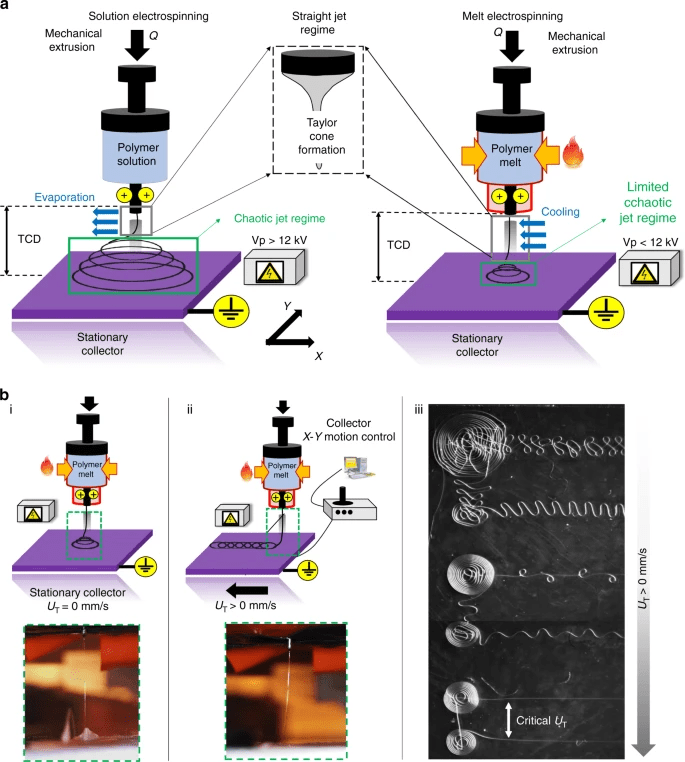

The article highlights the integration of melt electrowriting (MEW) with microfluidic bioprinting to create intricate tissue scaffolds. MEW, a high-precision additive manufacturing technique, allows for the fabrication of fine, microscale fiber networks that provide structural support to biofabricated tissues. By combining MEW with microfluidics, the researchers achieved precise control over the deposition of both the supporting polymer fibers and the embedded bioinks. This hybrid approach improves the mechanical stability of the printed constructs and enables the design of scaffolds with tailored microarchitectures, making it especially suitable for applications in tissue engineering and regenerative medicine where structural integrity is crucial.

Fig 1. Solution electrospinning (SES) vs. melt electrospinning (MES). The main differentiating feature between the two processes is the extent of the jet instabilities that arise from the electrostatic forces acting at the polymer jet-air interface

About Biological Lattice Industries (BLI)

Biological Lattice Industries (BLI) is a biofabrication startup dedicated to democratizing the field of biofabrication by providing affordable, scalable technology for a wide range of applications, including regenerative medicine and drug development. With a mission to make biofabrication accessible to all, BLI aims to drive innovation and change in biotechnology.

About Uni.Fund

Uni.Fund is an investment fund focusing on supporting high-impact technology startups in Greece. With a portfolio spanning various industries, Uni.Fund is committed to nurturing early-stage companies with transformative potential in fields such as biotechnology, software, and green technology.

Leave a comment