HITS-Bio (High-throughput Integrated Tissue Fabrication System for Bioprinting), develop from Dr. Ibrahim Ozbolat’s lab, has emerged as a system that integrates advanced digitally-controlled nozzle arrays (DCNA) to enable rapid, scalable bioprinting of tissue spheroids with improved accuracy and speed.

The HITS-Bio Platform

HITS-Bio leverages a multi-array nozzle system, the platform achieves:

- Improved Speed: Bioprinting rates that are 10 times faster than conventional techniques.

- High Viability: Over 90% cell viability in bioprinted constructs.

- Scalable Fabrication: Capability to bioprint larger tissue constructs more rapidly and precisely.

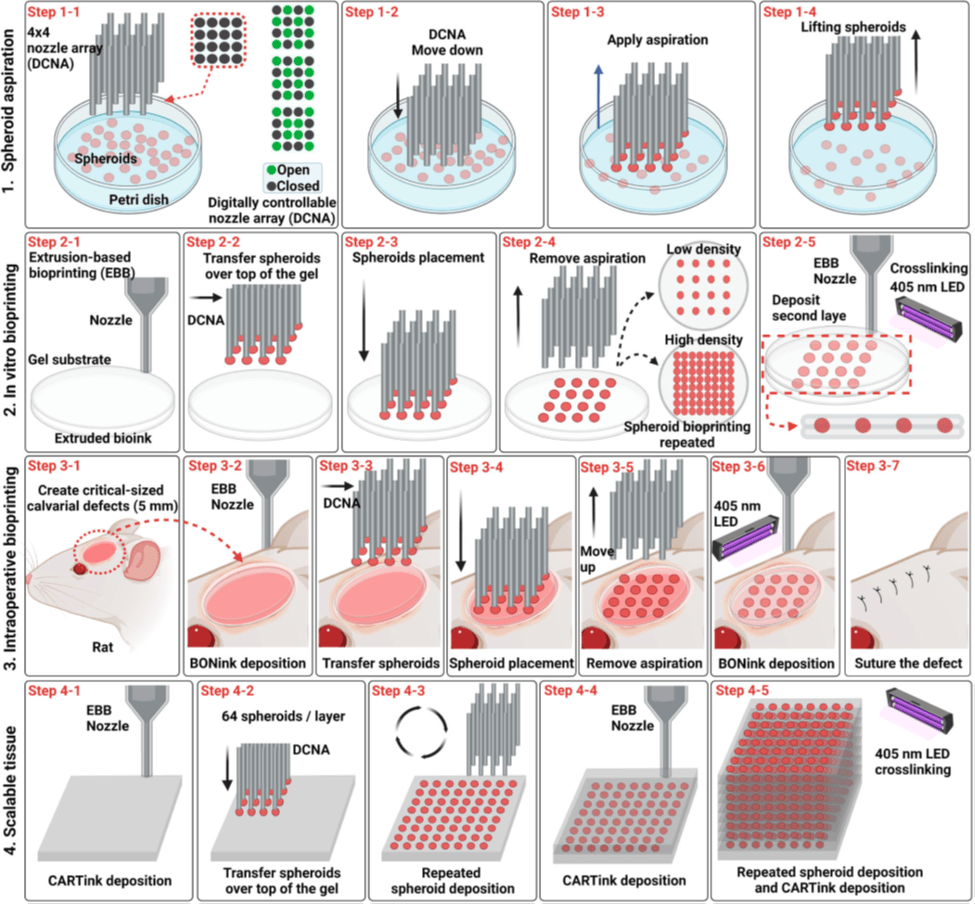

The system’s DCNA allows simultaneous handling of multiple spheroids, positioning them with spatial control. This innovation improves spheroid-based bioprinting from a labor-intensive, one-at-a-time process into a high-throughput solution.

Figure. Schematic of the HITS-Bio process. Image taken from the paper cited below.

Key Applications

- Intraoperative Bioprinting for Bone Regeneration

- HITS-Bio was tested in calvarial bone regeneration using microRNA-transfected human adipose-derived stem cell spheroids.

- Results in a rat model showed near-complete defect closure with over 90% bone coverage within six weeks.

- This capability holds promise for on-demand tissue fabrication during surgical procedures.

- Scalable Cartilage Tissue Fabrication

- The platform successfully produced cartilage constructs (~1 cm³) with approximately 600 chondrogenic spheroids in under 40 minutes.

- Constructs exhibited enhanced extracellular matrix (ECM) deposition, essential for tissue functionality.

Why HITS-Bio is a Breakthrough

HITS-Bio overcomes the limitations of existing bioprinting techniques, such as low throughput and insufficient precision. Its key innovations include:

- Customizable DCNA: Enables selective activation of nozzles, providing flexibility for various applications.

- Advanced Bioinks: Tailored formulations for bone and cartilage, ensuring compatibility and enhanced mechanical properties.

- High-Precision Software: A user-friendly interface ensures precise control over the bioprinting process, from positioning to patterning.

Future Directions and Clinical Potential

The success of HITS-Bio in fabricating scalable tissues and its intraoperative applications point toward its potential in clinical settings. Future enhancements, such as increasing nozzle arrays and integrating adaptive platforms for non-planar surfaces, could further expand its versatility.

HITS-Bio sets a higher benchmark in high-throughput bioprinting, opening avenues for scalable tissue engineering and regenerative therapies. Its ability to merge speed, precision, and scalability positions it as a novel tool in for bioprinting, paving the for potential advancements in personalized medicine and organ regeneration.

Original paper can be found here.

About Dr. Ibrahim T. Ozbolat

Dr. Ibrahim T. Ozbolat is a recognized researcher, innovator, and thought leader in the field of bioprinting. As a professor at Penn State University in the Department of Engineering Science and Mechanics and the Department of Biomedical Engineering, his work has advanced the science of 3D bioprinting for regenerative medicine.

Leave a comment