Introduction

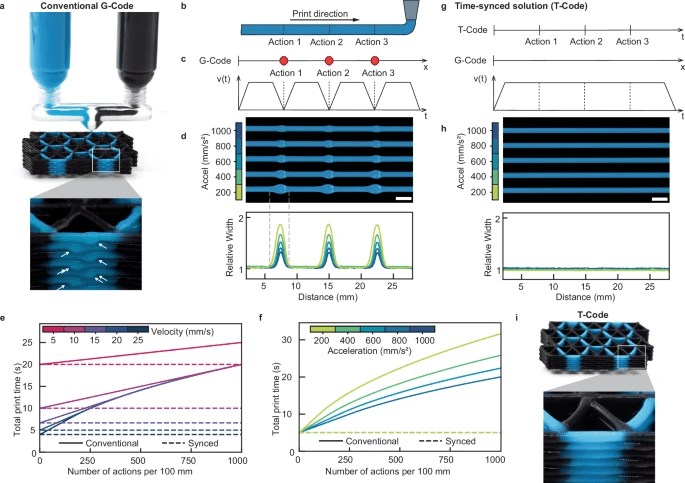

The field of bioprinting has made strides in recent years. However, despite advances in multifunctional 3D printheads, the standard G-Code used for print path execution presents a significant limitation: it forces interruptions in the print process whenever auxiliary controls, such as material switching or UV curing, are required. This leads to defects, reduced precision, and inefficient printing speeds. Enter Time Code (T-Code), a novel synchronization method from Jochen Mueller lab at Johns Hopkins that decouples auxiliary controls from print path execution, enabling seamless and uninterrupted multimaterial bioprinting.

The Challenge with G-Code in Bioprinting

G-Code, originally designed for CNC machines, remains the industry standard for controlling extrusion-based 3D printers, including those used in bioprinting. However, it operates in a line-by-line execution mode, meaning that any auxiliary command, such as switching bioinks or activating a crosslinking mechanism, requires the printer to stop momentarily. In bioprinting applications where maintaining the integrity of the printed structure is paramount, these interruptions can introduce defects such as over-extrusion, inconsistent material deposition, and compromised mechanical properties.

While solutions like linear advance exist to mitigate pressure buildup issues, they are primarily tailored for fused filament fabrication (FFF) rather than pressure-driven xtrusion systems used in bioprinting. These limitations necessitate a new approach to controlling multifunctional printheads.

Figure from paper: G-Code limitations and T-Code introduction

How T-Code Works

T-Code introduces a time-based synchronization mechanism that separates print path motion from auxiliary commands. This approach allows auxiliary functions, such as material switching, UV curing, and nozzle adjustments, to be executed in parallel with the continuous motion of the printhead. The key advantages of T-Code include:

- Uninterrupted Print Paths: Unlike G-Code, which forces the printer to halt for each auxiliary command, T-Code ensures a continuous, fluid printing process.

- Higher Precision: Reducing interruptions improves the accuracy of deposited bioinks, crucial for applications like vascularized tissue fabrication.

- Enhanced Speed: By allowing auxiliary commands to run independently, T-Code significantly reduces overall print time.

- Minimized Mechanical Stress: Eliminating frequent stops lowers the mechanical burden on the printer, extending its operational lifespan.

Implications for Bioprinting

1. Functional Gradients for Tissue Engineering

T-Code enables the fabrication of functionally graded biomaterials, crucial for engineering tissues with gradual compositional changes. For example, bone-cartilage interfaces and vascular grafts require smooth material transitions that G-Code-based printing struggles to achieve due to frequent interruptions.

2. Multimaterial Printing for Complex Tissue Structures

With T-Code, bioinks of different cell types or extracellular matrices can be co-extruded in a controlled manner, allowing for precise spatial patterning of cellular structures. This advancement is particularly useful for bioprinting organ-on-a-chip models and other high-fidelity tissue constructs.

3. Scalable and Parallelized Bioprinting

T-Code’s ability to synchronize multiple printheads independently opens the door to scalable bioprinting. Instead of printing single structures sequentially, multiple printheads can operate in parallel, significantly increasing throughput for applications such as regenerative medicine and drug screening platforms.

Future Outlook

The introduction of T-Code represents a step forward in bioprinting technology. As the demand for high-precision, multimaterial bioprinting grows, innovations like T-Code will be important to overcoming the limitations of traditional print path programming. Future developments may integrate T-Code into commercial bioprinting software, making it accessible to researchers and companies seeking to push the boundaries of regenerative medicine and tissue engineering.

By enabling high-speed, defect-free, and scalable bioprinting, T-Code is has potential to improve an tools in the next generation of biofabrication technologies.

To find out more, check out the publication here.

Leave a comment