A collaborative research team from the Massachusetts Institute of Technology (MIT) and the Polytechnic University of Milan (Polimi) has introduced a modular, printer-agnostic monitoring platform designed to enhance the quality and efficiency of 3D bioprinting for tissue engineering. This development addresses a longstanding challenge in the field: the lack of integrated process control, which often results in defects, inconsistent tissue structures, and material waste.

The new system integrates a compact digital microscope mounted alongside a bio-ink extrusion printhead, capturing high-resolution images of tissues as they are printed. Using an AI-driven analysis pipeline, the platform compares these images to the intended design in real time, enabling immediate detection of printing errors such as irregular filament dimensions or inconsistent bio-ink distribution. The platform’s compact design allows it to be installed on a variety of commercial and custom bioprinters, with an overall cost of less than $500.

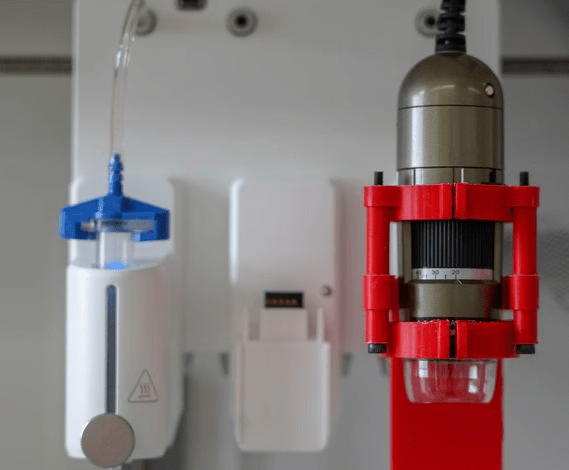

The compact design of the monitoring platform enables mounting it on a 3D bioprinter printhead next to the bio-ink extrusion printhead. Source: MIT.

By providing continuous feedback and automated parameter adjustments, this monitoring technology supports real-time quality assurance. It has already been implemented at MIT’s SHED bioprinting facilities and replicated at Polimi, creating an environment for collaborative data sharing. The approach is expected to improve reproducibility, reduce resource use, and accelerate the development of engineered tissues for applications in disease modeling, regenerative medicine, and implantable grafts.

About Ritu Raman

Ritu Raman is the Eugene Bell Career Development Chair of Tissue Engineering and an assistant professor of mechanical engineering at MIT. Her research focuses on building adaptive biological materials and devices that integrate living cells, with the goal of advancing regenerative medicine and medical device innovation.

For information directly to the system click here.

Leave a comment