Opening: A Spark on the Gulf Coast

In Pascagoula, Mississippi, something remarkable is taking shape at Singing River Health System. The Singing River Wound Care Center has become one of the first facilities in the nation to offer Tides Medical APLICOR 3D, a pioneering wound care technology that creates custom, 3D-printed grafts from a patient’s own tissue. In just 60 to 90 minutes, clinicians can take a small fat sample, process it into “bio-ink,” and print a graft that precisely fits the wound’s shape. For patients suffering from chronic diabetic ulcers, surgical wounds, and pressure injuries, this innovation offers new hope—reducing rejection risk and accelerating healing. What began as a localized pilot is now emerging as a blueprint for how regenerative biofabrication can enter mainstream clinical workflows.

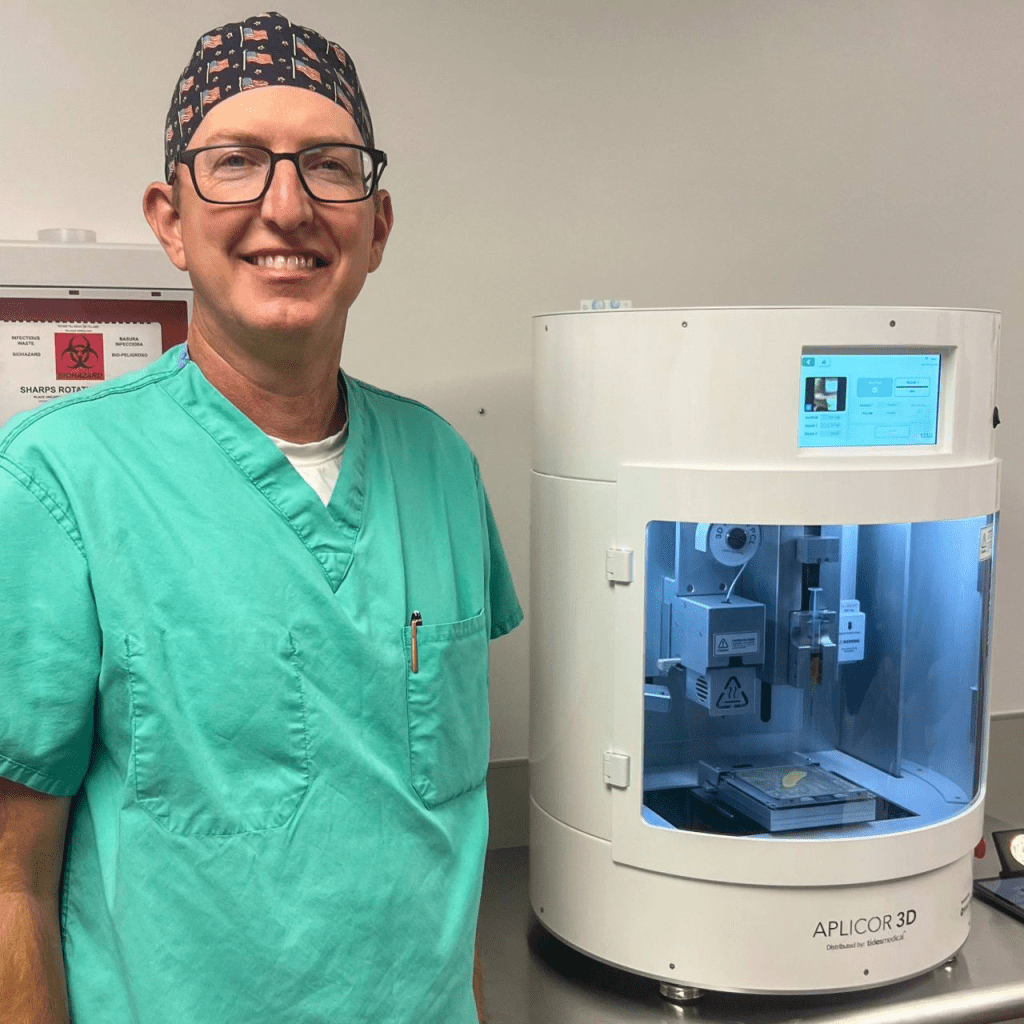

Photo Credit to Signing River Health System

The Business Model: Biofabrication Meets Health System

At its core, APLICOR 3D delivers personalization—each graft is uniquely tailored to the patient’s wound, improving fit and biological integration. Because it uses the patient’s own tissue, the risk of immune rejection is significantly reduced. The process is fast and operationally simple, taking less than two hours from imaging to graft placement, and requires minimal infrastructure compared to conventional tissue-engineering approaches. This makes it attractive to hospitals seeking cutting-edge therapies that don’t require heavy capital investment.

The APLICOR 3D business model centers on strategic health system partnerships rather than individual clinic sales. Singing River serves as the flagship reference site, proving both technical feasibility and patient value. Expansion will rely on generating robust case studies that highlight improved healing rates, lower complication frequencies, and better cost-efficiency compared to standard grafts. Training programs, clinical protocols, and supply-chain management for scaffold kits will accompany each new installation, ensuring consistency across locations.

The Next Health System: Who Should Be Next (and Why)

As APLICOR 3D looks beyond Mississippi, the question is not if more systems will adopt it—but which will be next. Ideal partners are health systems that combine a culture of innovation with a strong wound-care focus, significant diabetic or vascular patient populations, and existing research or translational infrastructure. Regions such as the Southeast and Sun Belt are natural growth corridors due to their high incidence of chronic wounds.

The Big Picture

APLICOR 3D represents more than a single wound-care innovation—it is a platform for distributed biomanufacturing at the point of care. Each clinic or hospital that installs the technology effectively becomes a mini tissue-engineering facility, capable of producing living grafts tailored to each patient. As adoption expands, the cumulative network of APLICOR 3D sites forms a living database of outcomes, driving continual improvement and data-driven insight into regenerative healing.

In the long run, the same approach—using imaging, rapid bioprinting, and autologous cells—could extend far beyond wound repair into soft-tissue reconstruction, skin regeneration, and implant-tissue interfaces. What began on the Gulf Coast could become the foundation of a new medical paradigm: hospitals that not only treat patients but also manufacture personalized tissue therapies in-house.

APLICOR 3D’s journey from Pascagoula to the nation signals the arrival of an era where biofabrication is not confined to research labs—it’s happening in the clinic, one patient at a time.

About Tides Medical

Tides Medical is redefining regenerative wound care by moving beyond traditional graft supply into personalized, on-site tissue manufacturing. Known for its amniotic grafts and physician-support programs, the company has expanded its mission with APLICOR 3D, an innovative system that uses a patient’s own fat cells to 3D-print custom wound grafts in about an hour. Through this technology, Tides transforms clinics into miniature biomanufacturing hubs, enabling surgeons to create autologous grafts tailored to each patient’s wound geometry. Early deployments, such as at Singing River Health System in Mississippi, demonstrate the potential to reduce healing times and complications while lowering costs. By coupling clinical partnerships with reimbursement strategy and operational simplicity, Tides is positioning itself at the forefront of distributed biofabrication—turning the promise of regenerative medicine into a practical reality at the point of care.

For more info click here.

Leave a comment