restor3d has announced a major clinical milestone: the first surgeries using the iTotal Identity™ CR 3DP Porous Fully Personalized Total Knee Replacement System, the first cementless knee implant system built entirely around patient-specific design and advanced 3D-printed porous structures.

This marks a transformative moment in orthopedics—a shift from standardized implants to fully individualized joint replacements tailored to each patient’s anatomy, biomechanics, and tissue interface.

What Makes the iTotal Identity™ 3D-Printed Knee Different?

Unlike conventional knee replacements that rely on off-the-shelf geometries, the iTotal Identity system is built on three pillars:

1. CT-Based Planning

Each implant begins with a detailed CT scan, which captures:

- The patient’s bone geometry

- Alignment

- Joint line

- Soft tissue constraints

This imaging input becomes the blueprint for a completely personalized replacement.

2. Automated Personalization Workflow

restor3d’s software platform uses the CT scan to automatically generate:

- A custom implant geometry

- A personalized fixation strategy

- Patient-specific implant alignment parameters

This reduces manual design time and increases consistency—critical for scaling personalized implants across busy surgical practices.

3. TIDAL Technology™: Next-Generation 3D-Printed Porous Structures

At the core of the system is restor3d’s proprietary TIDAL Technology™, an advanced additive-manufactured porous architecture engineered for:

- Cementless fixation

- Enhanced bone ingrowth

- Improved load distribution

- Long-term biological stability

Unlike traditional porous coatings bonded to solid metal, TIDAL porous architecture is printed as an integrated structure, allowing:

- Controlled pore sizes

- Graded porosity

- Anatomically optimized mechanical properties

This results in a stronger biological interface and reduces risks associated with cemented fixation.

Clinical Significance: A New Era of Personalized Knee Arthroplasty

The inaugural clinical procedures were performed by Dr. William Berghoff at Parkview Orthopedic Hospital, achieving successful outcomes in the first cohort of patients.

This limited market release represents several significant advances:

A. Fully Personalized Fit

Implants can be matched to each patient’s:

- Bone curvature

- Joint line

- Tibial slope

- Femoral geometry

This has the potential to reduce:

- Malalignment

- Soft-tissue imbalance

- Postoperative pain

- Implant revision rates

B. Cementless Implantation

Orthopedics is increasingly moving toward cementless fixation, which may:

- Reduce operative times

- Improve long-term biological integration

- Lower complications associated with cement debris and loosening

restor3d’s porous architecture is purpose-built for this shift.

C. Precision Fixation and Functionality

3D-printed porous structures allow implants to mirror the mechanical behavior of cancellous bone, improving:

- Load sharing

- Stability

- Range of motion

- Functional outcomes

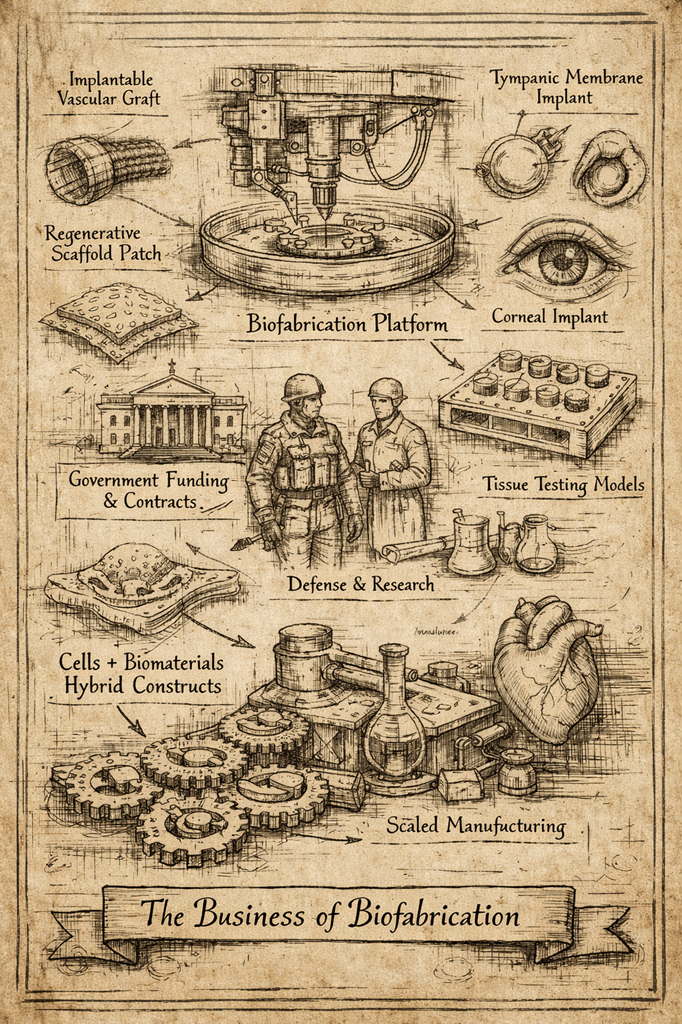

Why This Matters for the Biofabrication Industry

The restor3d system exemplifies the next phase of medical 3D printing:

- Patient-specific implants rather than size matrices

- Cementless, biologically integrated surfaces rather than adhesives

- Automated digital workflows that turn imaging into personalized implant geometry

- Additive manufacturing as core technology, not as a coating or niche feature

In orthopedics—one of the largest and most mature implant markets—the shift toward personalization has been slow due to workflow complexity, cost, and regulatory challenges. restor3d’s success demonstrates that:

- Automation can remove cost and fabrication barriers

- 3D printing can deliver clinically meaningful customization

- Surgeons increasingly expect implants that match each patient’s anatomy, not the other way around

This milestone shows that biofabrication is ready not only to match the performance of legacy implants—but surpass it.

What’s Next for restor3d

With successful first-in-human cases completed, restor3d will:

- Gather early clinical performance data

- Expand surgeon training

- Prepare for full commercial launch

- Scale manufacturing for personalized implant production

As clinical adoption grows, restor3d is positioned to lead the broader movement toward truly individualized orthopedic medicine.

About restor3d

restor3d is a Durham-based medical device company specializing in patient-specific orthopedic implants and instrumentation enabled by advanced 3D printing, biomaterials, and digital surgical planning. The company integrates imaging data, proprietary design algorithms, and additive manufacturing to produce implants that precisely match each patient’s anatomy and biomechanics. restor3d’s portfolio includes solutions for spine, foot & ankle, sports medicine, and trauma, with an emphasis on porous structures that promote osseointegration and long-term stability. The company has also expanded its capabilities through acquisitions—including Conformis—to build one of the industry’s most comprehensive personalized musculoskeletal platforms. Backed by leading investors and collaborations with major health systems, restor3d aims to transform surgical outcomes through fully integrated personalized surgery workflows, from pre-operative planning to customized implants and instruments.

Leave a comment